In-Drum

BULK POWDER ELEVATOR

Delivers powder to the top of the drum!

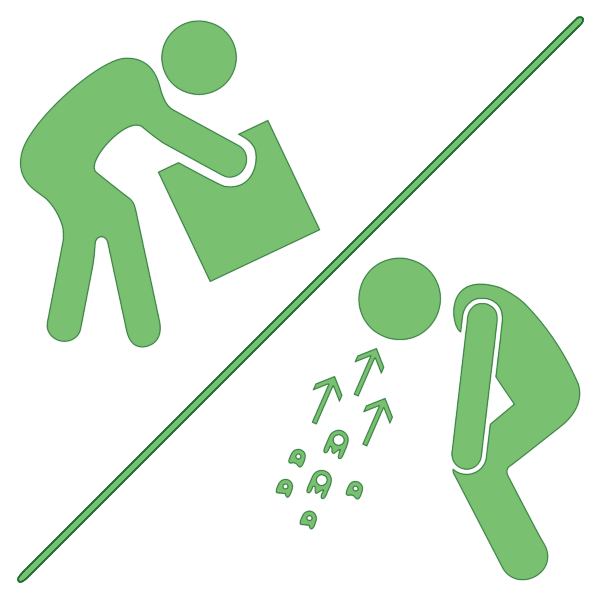

A solution for industries struggling with the manual extraction of powder shipped in drums!

• Pharmaceutical • Nanoparticles • Chemical • Nutraceutical • Fine Metals • 503B • Plastics • Biotech • Cosmetic • Food

Drumwaiter™ raises powder to the top of the drum making it directly accessible and visible. The benefits are faster, more thorough and cleaner removal, decreased waste, lower PPE cost, and improved comfort and safety for your employees. Drumwaiter™ radically enhances the efficiency and effectiveness of powder extraction inside of a Bulk Powder Enclosure, Isolator or Downflow Booth.

Drumwaiter™ improves operations in four critical areas.

Drumwaiter™ is easier, faster, less expensive, and cleaner!

Get instant access to our growing library of videos and resources!

Drumwaiter™ is a product developed in response to industry need!

The goal of our research and development was to develop a safer, more efficient and more effective way to access potent bulk powders while reducing cost and inherent inefficiencies that exist across the industry.

The result of this research and development is now available in Drumwaiter™.

"Manual extractions from the bottom of a drum have been too difficult for too long!"

Richard C. Albers, Inventor

ILLUSTRATION ONLY

Drumwaiter™, what is under the lid?

Drumwaiter™ has drawn on over 40 years of experience in Pharmaceutical Products, Science, Research and Manufacturing, to develop a cost effective, low pressure, pneumatic lift device, designed specifically for the purpose of raising potent powder to a more accessible level within the drum.

The Drumwaiter™ proprietary, patent-pending, In-Drum Elevator, is installed into a drum prior to filling. The In-Drum Elevator can fit almost any size or type of drum and has no contact with contents in a lined drum. Activated by an external Drumwaiter™ Footpedal, the two components work together to provide hands free operation to raise, lower, or hold the contents of a drum at any height repeatedly until the drum is empty. When the drum is empty, the In-Drum Elevator is incinerated or disposed of with the drum while the external Footpedal can be reused.